Fireplace Dampers & Chimney Dampers Buyer's Guide

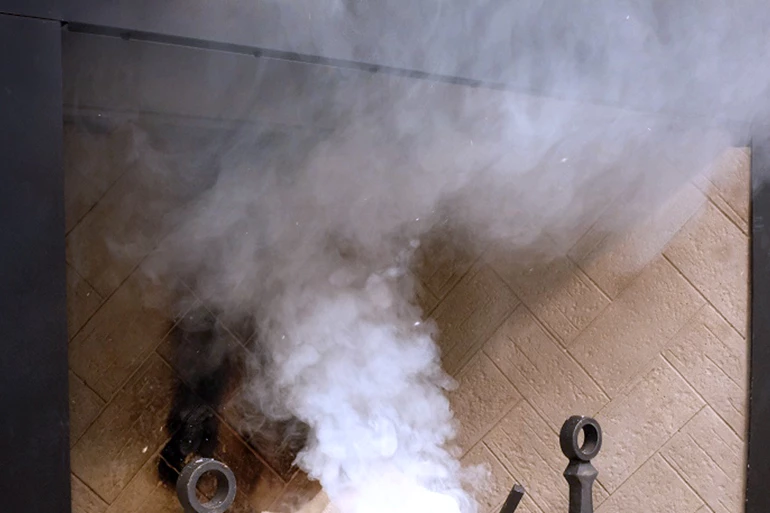

- Smoke back drafting into the home

Have you ever watched someone fumbling with a damper on a smoky fire? A fireplace damper acts as a gateway for the chimney, opening to let air pass through or remaining shut to keep the chimney sealed. They're a simple mechanism, but how do you know when they should be open or closed? And should they ever be left partially open?

Here's a guide to the different kinds of chimney dampers and how to operate the different styles. You'll also find tips on how to replace or install them.

What is a Fireplace Damper?

A fireplace damper is a simple flap that opens and closes inside the flue of your fireplace. When closed, it seals off the chimney so that warm air from your house doesn't escape. (No one enjoys paying to heat the outdoors.) When open, it allows the fire to vent properly and let the smoke go up the chimney.

Customer Q&A with Product Specialists

Thank you for reaching out!

Thank you for your interest in our products. We've received your question and will get back to you shortly — usually within the hour but always within 1 business day. To ensure you receive our response, please add our email address (info@efireplacestore.com) to your email whitelist or address book.

In the meantime, while we prepare our response, keep an eye on your inbox for an email from us. We'll be sending you our exclusive Buyer's Guide, packed with valuable information to assist you in making the best decision for your needs.

If you have any further questions or need immediate assistance, feel free to reach out to us directly at 1-800-203-1642.

Thank you again for choosing eFireplaceStore.com!